Introduction

The role that pharmaceutical manufacturers play in any healthcare system is critical. However, the processes involved in manufacturing often have a significant impact on the environment. In recent years, sustainability has become a focal point in the industry. This post explores how sustainable processes are being adopted in pharmaceutical manufacturing to reduce environmental footprints and ensure a greener future.

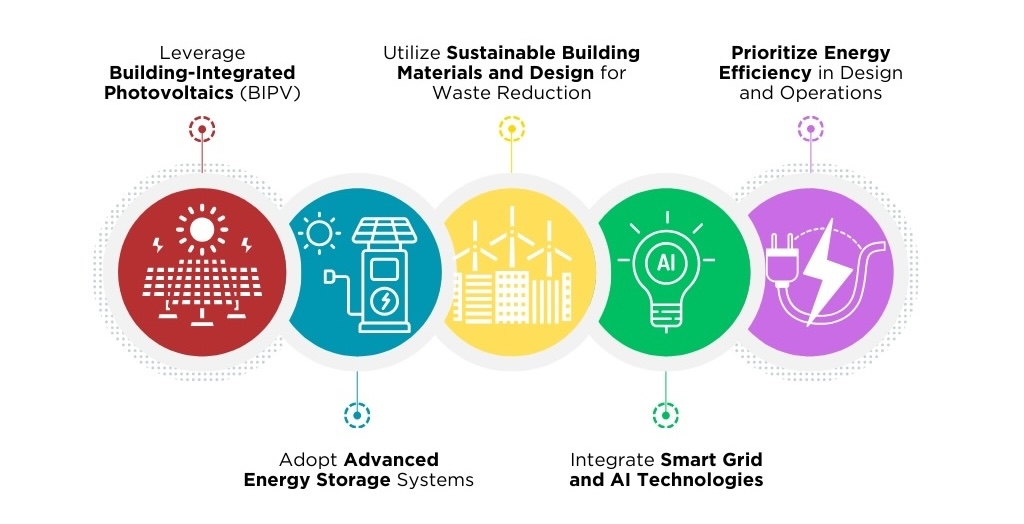

1. Renewable Energy Integration

Pharmaceutical manufacturing facilities are increasingly incorporating solar and wind power into their operations. This shift not only reduces dependency on fossil fuels but also significantly cuts down on greenhouse gas emissions.

2. Energy Efficiency Technologies

Energy efficiency technologies play a crucial role in reducing energy consumption. Examples of such technologies include energy-efficient HVAC systems, optimized chiller plants, and smart lighting. These upgrades improve energy efficiency across all stages of the manufacturing process.

3. Green Chemistry

Green chemistry focuses on designing products and processes that minimize the production of hazardous substances. By adopting green chemistry principles, pharmaceutical companies can lower the environmental impact of their manufacturing processes. This includes reducing waste, using safer solvents, and improving reaction efficiencies.

4. Waste Reduction and Management

An effective waste management system is essential for sustainable manufacturing. Pharmaceutical companies are finding ways to minimize waste generation by optimizing production processes and recycling materials. The concept of a circular economy, which emphasizes recycling and reusing, is gaining traction in the industry.

5. Water Conservation

Pharmaceutical manufacturing is water-intensive. To address this, companies are implementing water conservation techniques such as recycling wastewater, using water-efficient technologies, and adopting closed-loop systems to minimize water consumption.

6. Sustainable Packaging

Sustainable packaging solutions are being developed to reduce environmental impact. These solutions include using recyclable materials, reducing packaging size, and minimizing packaging waste. Sustainable packaging contributes to a product’s overall lifecycle sustainability.

7. Regulatory Compliance and Reporting

Regulatory bodies are becoming increasingly stringent regarding sustainability in pharmaceutical manufacturing. Companies are required to report and comply with environmental regulations, fostering trust with stakeholders and driving continuous improvement in sustainability practices.

Conclusion

Sustainable practices in pharmaceutical manufacturing are essential for reducing environmental footprints and building a greener future. By embracing renewable energy, green chemistry, effective waste management, water conservation, and sustainable packaging, the pharmaceutical industry can take significant strides towards sustainability.