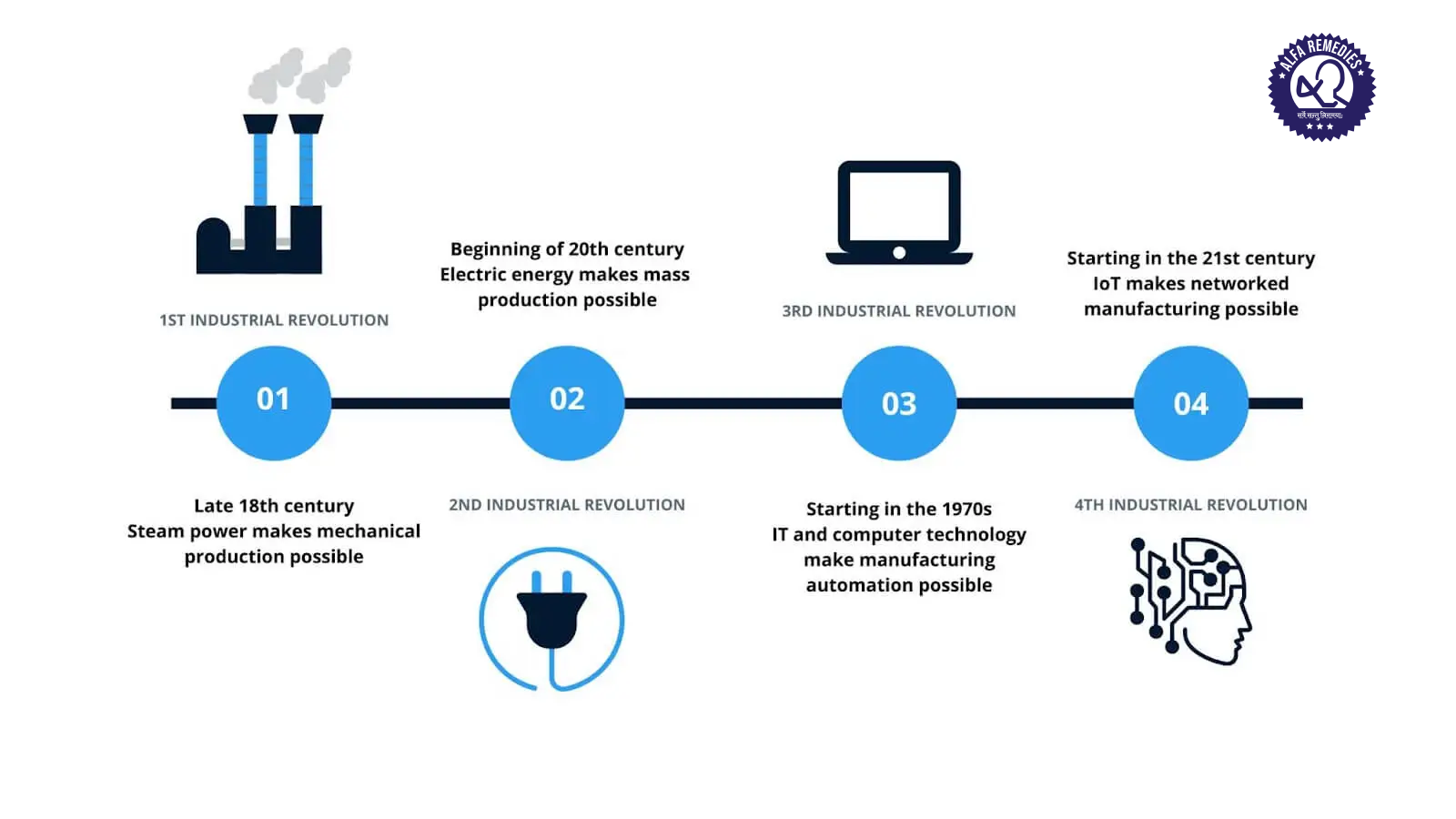

As the world moves deeper into the fourth industrial revolution, known as Industry 4.0, the pharmaceutical sector is undergoing transformative changes. Smart factories, driven by cutting-edge technologies such as artificial intelligence (AI), the Internet of Things (IoT), big data, and machine learning, are redefining how pharmaceutical products are manufactured. Alfa Remedies, a leading pharma manufacturer in Ambala Cantt, is embracing these innovations to enhance efficiency, precision, and quality in pharmaceutical production, ensuring timely Pan India delivery.

This blog will explore the impact of Industry 4.0 innovations on pharma manufacturing, how smart factories operate, and how Alfa Remedies is leveraging these technologies to stay ahead of the curve in a competitive industry.

What Are Smart Factories?

A smart factory is a highly digitized and connected production facility that uses advanced technologies to optimize manufacturing processes. Unlike traditional factories, smart factories leverage automation, real-time data, and intelligent systems to make data-driven decisions that enhance production efficiency, reduce downtime, and improve product quality.

In pharmaceutical manufacturing, smart factories are revolutionizing how medicines are produced, packaged, and distributed. By integrating Industry 4.0 innovations, these factories can operate with minimal human intervention, ensuring that every step of the production process is streamlined and optimized for maximum output.

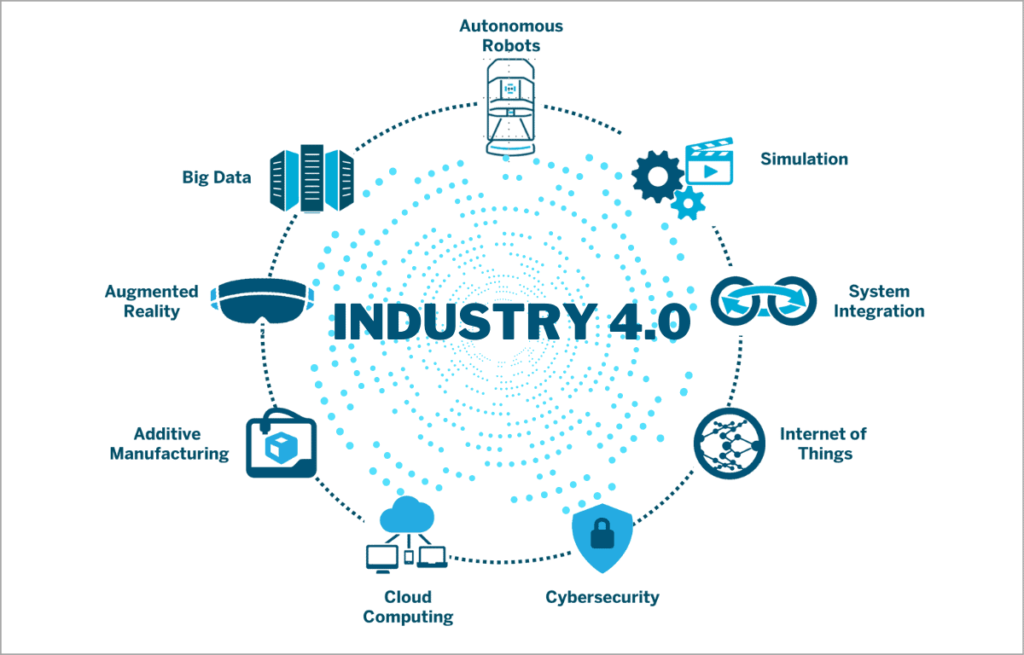

Key Industry 4.0 Innovations in Pharma Manufacturing

Industry 4.0 is driven by a combination of technologies that work together to create smarter, more efficient production environments. Here are some of the key innovations that are transforming the pharmaceutical industry:

1. Internet of Things (IoT) and Real-Time Monitoring

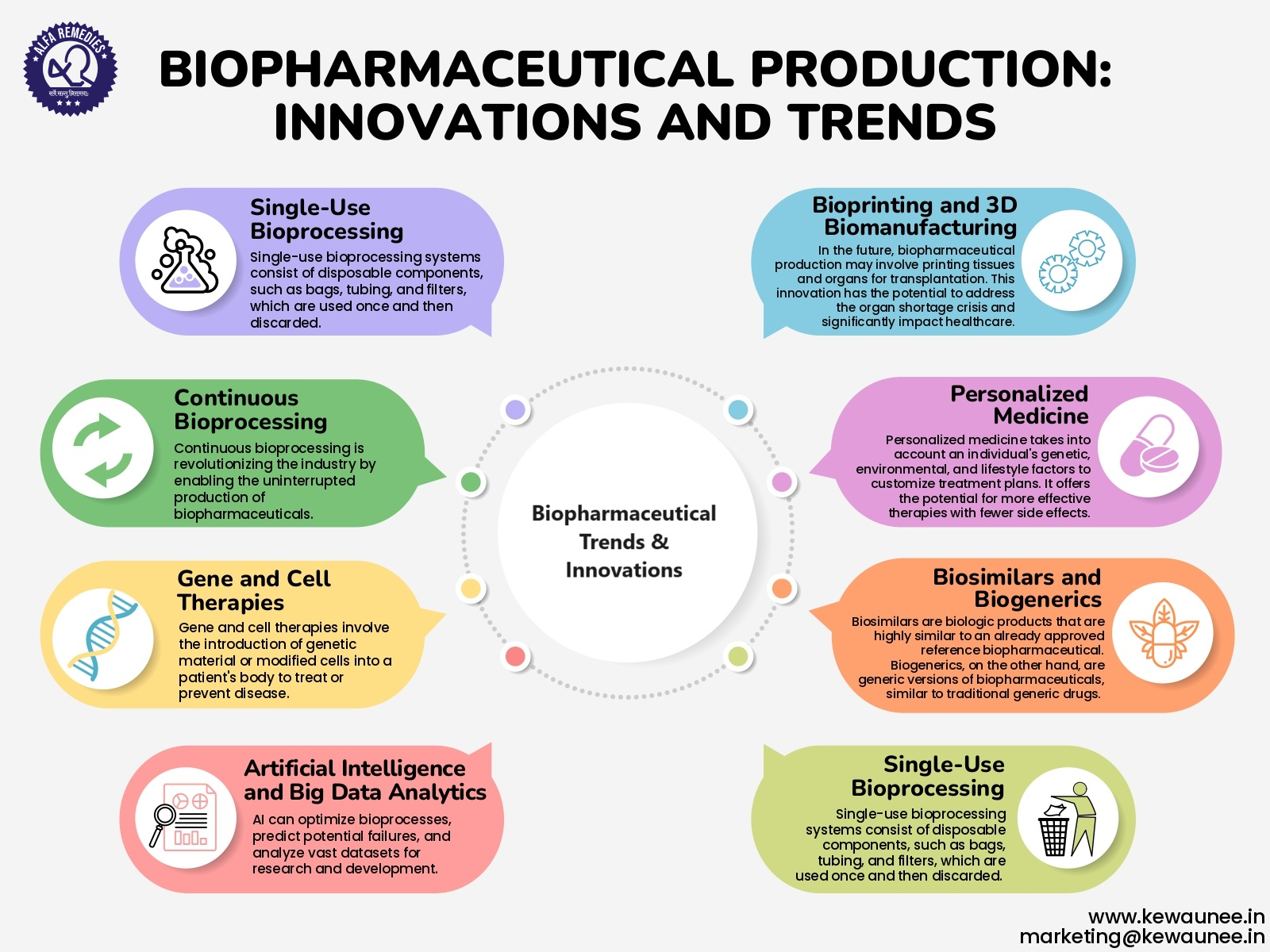

The Internet of Things (IoT) allows different devices and machines in a factory to communicate with each other, collecting and sharing data in real-time. In pharma manufacturing, IoT-enabled sensors can monitor every aspect of the production process, from temperature control in cleanrooms to equipment performance. This real-time monitoring helps manufacturers like Alfa Remedies identify potential issues before they escalate, ensuring consistent product quality and reducing waste.

2. Artificial Intelligence (AI) and Machine Learning

AI and machine learning are playing a significant role in optimizing pharmaceutical production. These technologies enable smart factories to analyze large amounts of data, identifying patterns and predicting future trends. In the context of pharma manufacturing, AI can help optimize production schedules, reduce bottlenecks, and even forecast future demand for certain medicines, allowing companies like Alfa Remedies to plan production accordingly.

3. Big Data and Predictive Analytics

Big data is crucial to smart factory operations, as it provides insights into every aspect of the manufacturing process. By collecting and analyzing data from multiple sources, manufacturers can make more informed decisions. Predictive analytics, a subset of big data, allows companies to predict potential equipment failures or product quality issues before they occur. This proactive approach minimizes downtime and ensures consistent, high-quality production.

4. Advanced Automation and Robotics

Automation and robotics are essential components of Industry 4.0, enabling the seamless execution of repetitive and complex tasks. In a smart pharma factory, robots can handle tasks such as product assembly, packaging, and even quality control. Automation also reduces the margin for human error, leading to higher precision and consistent output. At Alfa Remedies, we integrate these technologies to ensure efficient, error-free production lines.

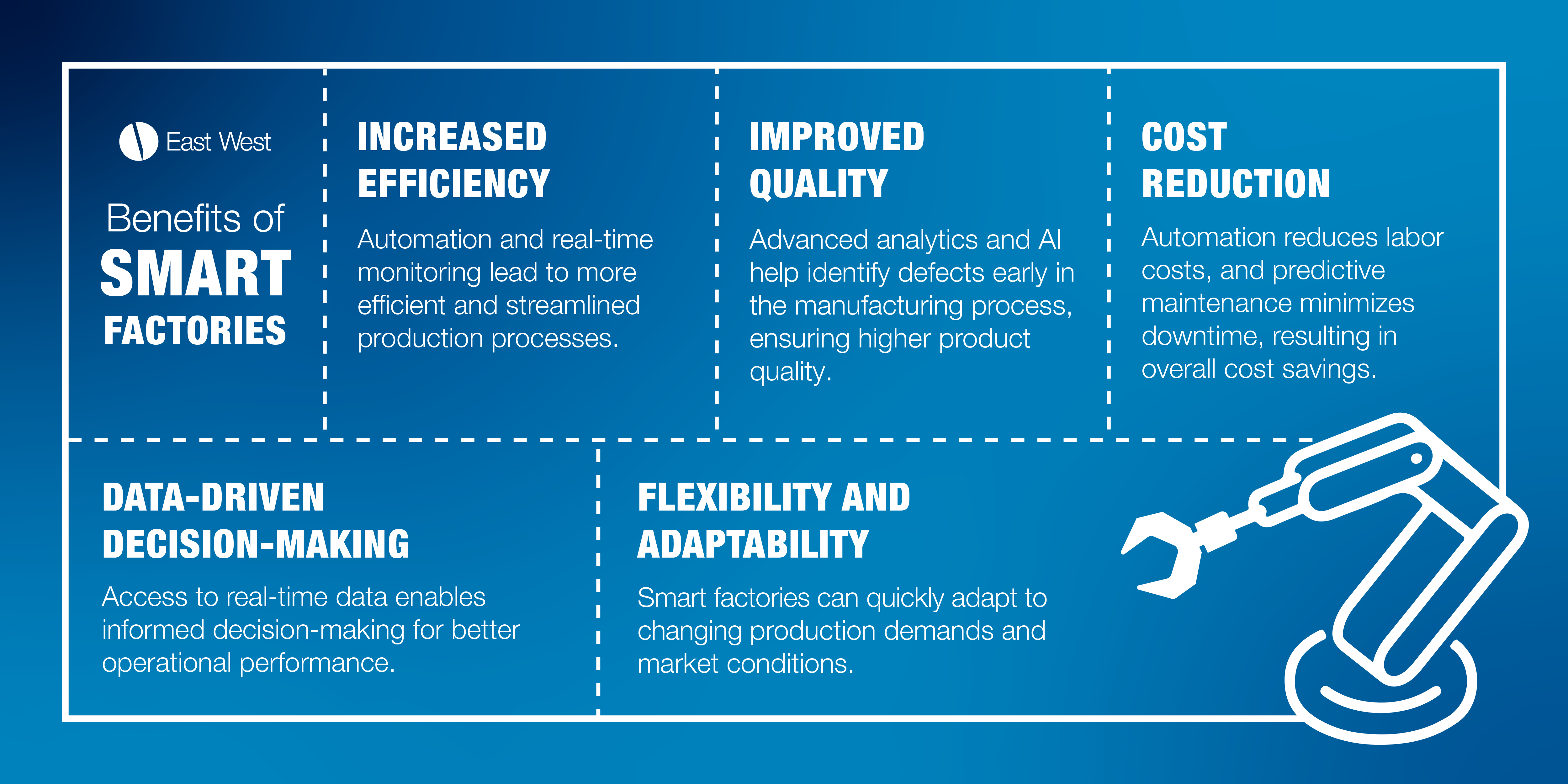

How Smart Factories Benefit Pharma Manufacturing

Smart factories are more than just a collection of advanced technologies. They offer a host of benefits that directly impact pharma manufacturing:

- Increased Efficiency: Automation, AI, and IoT allow for faster production cycles, reducing bottlenecks and optimizing resource use.

- Improved Product Quality: Real-time monitoring and predictive analytics help identify and address quality issues before they affect the final product.

- Cost Savings: By minimizing waste, reducing downtime, and streamlining operations, smart factories help cut production costs.

- Regulatory Compliance: Smart factories ensure adherence to Good Manufacturing Practices (GMP) and other regulatory requirements through precise data tracking and documentation.

- Scalability: Smart factories can easily adapt to changes in production demand, allowing manufacturers to scale operations up or down as needed.

Alfa Remedies: Pioneering Industry 4.0 in Pharma Manufacturing

As a leading pharma manufacturer in Ambala Cantt, Alfa Remedies is committed to embracing Industry 4.0 innovations to enhance our production capabilities. Here’s how we’re leveraging smart factory technologies:

1. Real-Time Data and IoT Integration

At Alfa Remedies, we have implemented IoT-enabled systems to monitor every stage of the production process. This real-time data helps us maintain strict control over environmental conditions, ensuring that our products meet the highest standards of quality and safety.

2. AI-Driven Production Optimization

We use AI-powered systems to analyze production data and make recommendations on how to optimize processes. This helps us reduce production cycle times, minimize waste, and enhance overall efficiency, enabling us to deliver products faster without compromising quality.

3. Automation and Robotics for Efficiency

Automation and robotics are integral to our manufacturing operations. From automated mixing and packaging systems to robotic arms that handle sensitive tasks, we ensure that our production lines run smoothly and efficiently, allowing us to meet the growing demand for pharmaceuticals across India.

4. Predictive Maintenance with Big Data

By leveraging big data and predictive analytics, Alfa Remedies ensures that our equipment remains in top condition. Predictive maintenance allows us to anticipate potential machinery failures and schedule repairs before they impact production. This proactive approach reduces downtime, ensuring that our manufacturing processes remain uninterrupted and efficient.

5. Enhanced Supply Chain Integration

Our smart factory setup includes the integration of digital supply chain management tools. By connecting suppliers, production, and distribution systems through advanced software platforms, we maintain visibility and control over our entire supply chain. This allows us to ensure timely Pan India pharma delivery and quickly adapt to changes in demand or disruptions in the supply chain.

The Future of Pharma Manufacturing: Embracing Industry 4.0

Industry 4.0 is not just a trend but the future of pharmaceutical manufacturing. As digital transformation continues to reshape industries worldwide, pharma manufacturers must adopt these technologies to remain competitive and meet the growing demands for innovation, quality, and efficiency.

At Alfa Remedies, we are committed to staying ahead of these advancements by continuously investing in smart factory technologies and other Industry 4.0 innovations. This approach enables us to deliver superior pharmaceutical products while maintaining the flexibility to meet evolving market needs.

Ensuring Reliable Pan India Pharma Delivery

One of the most significant advantages of our smart factory technology is its impact on our ability to deliver high-quality pharmaceutical products across India. Our integration of real-time data monitoring, AI, and predictive analytics ensures that we can produce and distribute medicines efficiently, regardless of location. As a result, Alfa Remedies continues to provide Pan India pharma delivery with speed and precision, ensuring that patients receive the medicines they need, when they need them.

Conclusion

Smart factories and Industry 4.0 innovations are revolutionizing pharmaceutical manufacturing, driving improvements in efficiency, quality, and scalability. At Alfa Remedies, we are proud to be at the forefront of this transformation, leveraging cutting-edge technologies to build a more resilient, innovative, and efficient production environment. Our commitment to embracing these advancements ensures that we continue to deliver high-quality medicines to healthcare providers across India.