The journey from raw materials to lifesaving medicines is a complex, carefully controlled process that ensures the highest levels of quality, safety, and efficacy. At Alfa Remedies, a leading pharma manufacturer in Ambala Cantt offering Pan India delivery, we take pride in our rigorous approach to pharmaceutical production. Each step of our process, from sourcing raw materials to delivering the final product, is designed to ensure that every medicine we produce is safe and effective.

In this blog, we take you behind the scenes of our production process, showcasing how Alfa Remedies transforms raw materials into medicines that save lives.

Sourcing High-Quality Raw Materials

The foundation of any pharmaceutical product is the quality of its raw materials. At Alfa Remedies, we carefully source raw materials from trusted suppliers who meet our stringent quality and safety standards. We work only with certified suppliers who provide us with the highest-quality active pharmaceutical ingredients (APIs) and excipients.

Each batch of raw materials undergoes comprehensive testing in our laboratories to ensure it meets the required specifications for purity, potency, and safety before being approved for use in production. This ensures that we are starting with the best possible foundation for our medicines.

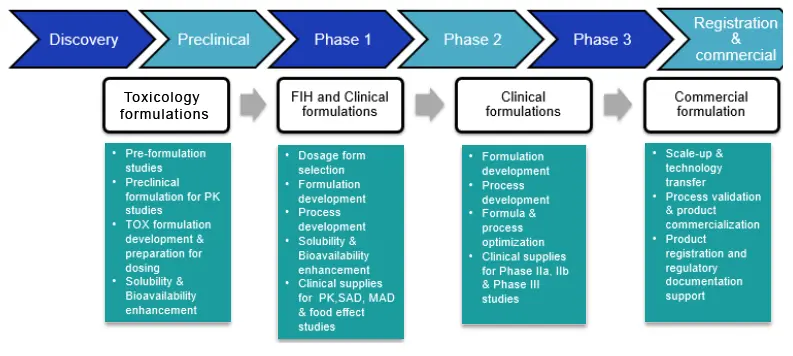

Manufacturing Process: From Formulation to Production

Once raw materials are approved for use, our skilled team of scientists and engineers begins the formulation process. The goal is to develop a formulation that is not only effective but also stable, safe, and easy to administer. Whether we are producing tablets, capsules, injectables, or other dosage forms, every formulation is carefully designed to meet the therapeutic needs of patients.

1. Advanced Technology and Equipment

Our state-of-the-art manufacturing facilities are equipped with advanced technologies that ensure precision and efficiency throughout the production process. Automated systems help reduce the risk of human error, improve consistency, and allow us to scale production to meet demand.

2. GMP-Certified Production Facilities

At Alfa Remedies, all of our manufacturing processes are conducted in GMP-certified facilities. This certification ensures that every step of the production process is conducted according to strict guidelines that guarantee the quality, safety, and efficacy of the medicines we produce. From the mixing of raw materials to the packaging of the final product, we follow precise protocols to maintain the highest standards of production.

Quality Control: Ensuring Safety and Efficacy

At Alfa Remedies, quality control is an integral part of our production process. We conduct rigorous testing at every stage of manufacturing to ensure that our medicines meet the highest standards of quality, safety, and efficacy. This includes testing raw materials, in-process testing during manufacturing, and final product testing before release.

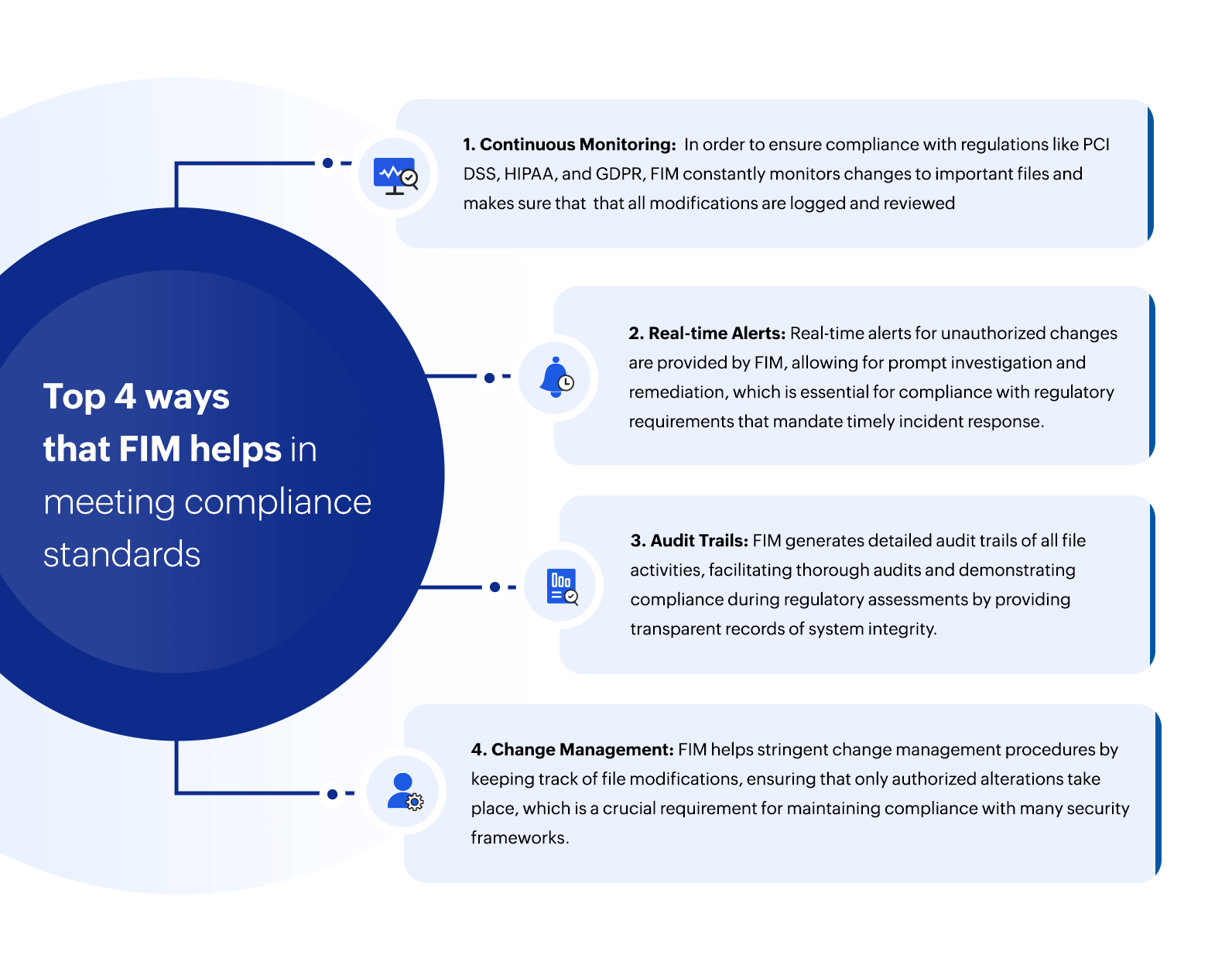

1. In-Process Quality Checks

During the production process, we perform in-process quality checks to ensure that everything is running smoothly and that the product being manufactured meets our specifications. This allows us to catch any potential issues early in the process, ensuring that only the highest-quality products move forward to the next stage of production.

2. Final Product Testing

Before any product is released for distribution, it undergoes final testing in our quality control laboratories. This testing ensures that the product meets all regulatory requirements for safety, purity, and efficacy. Only after passing these tests is the product approved for release.

Packaging and Labeling: Ensuring Integrity and Compliance

Once a product has passed all quality control checks, it moves to the packaging stage. At Alfa Remedies, we use advanced packaging technologies to ensure that our products are packaged in a way that maintains their integrity and protects them from contamination or damage during storage and transportation.

Our packaging and labeling processes are fully compliant with all regulatory requirements, ensuring that our products are clearly labeled with accurate information about their contents, dosage, and usage instructions. This not only ensures compliance but also helps patients and healthcare providers use our products safely and effectively.

Pan India Delivery: Ensuring Access to Medicines Nationwide

One of the key elements of Alfa Remedies’ commitment to quality is ensuring that our products are delivered to patients across India safely and on time. Our Pan India delivery network ensures that patients in every corner of the country have access to the lifesaving medicines they need.

We work with trusted logistics partners and use advanced tracking technologies to monitor the transportation of our products, ensuring that they reach their destinations quickly and safely. Our goal is to make high-quality medicines accessible to all, regardless of location.

Commitment to Innovation and Improvement

At Alfa Remedies, we are always looking for ways to improve our manufacturing processes and the quality of our products. We invest in the latest technologies and continuously train our staff to stay at the forefront of pharmaceutical innovation. By doing so, we ensure that we are always producing the most effective, safe, and affordable medicines possible.

Conclusion

From the careful selection of raw materials to the final delivery of lifesaving medicines, every step of Alfa Remedies’ production process is designed to ensure the highest levels of quality, safety, and efficacy. Our state-of-the-art facilities, rigorous quality control processes, and commitment to innovation enable us to produce high-quality medicines that make a real difference in the lives of patients across India.

To learn more about Alfa Remedies’ manufacturing capabilities or to partner with us, contact us today.