In the pharmaceutical industry, continuous manufacturing has emerged as a game-changing approach to improve efficiency and ensure the highest levels of quality assurance. As one of the leading pharma manufacturers in Ambala Cantt, Alfa Remedies has adopted this cutting-edge method to streamline its production processes and maintain consistent quality across all products. With continuous manufacturing, Alfa Remedies is not only boosting efficiency but also enhancing its Pan India pharma delivery services to meet the ever-growing healthcare demands.

This blog explores the benefits of continuous manufacturing in pharmaceutical production, highlighting its impact on efficiency, quality assurance, and the future of the industry.

What is Continuous Manufacturing?

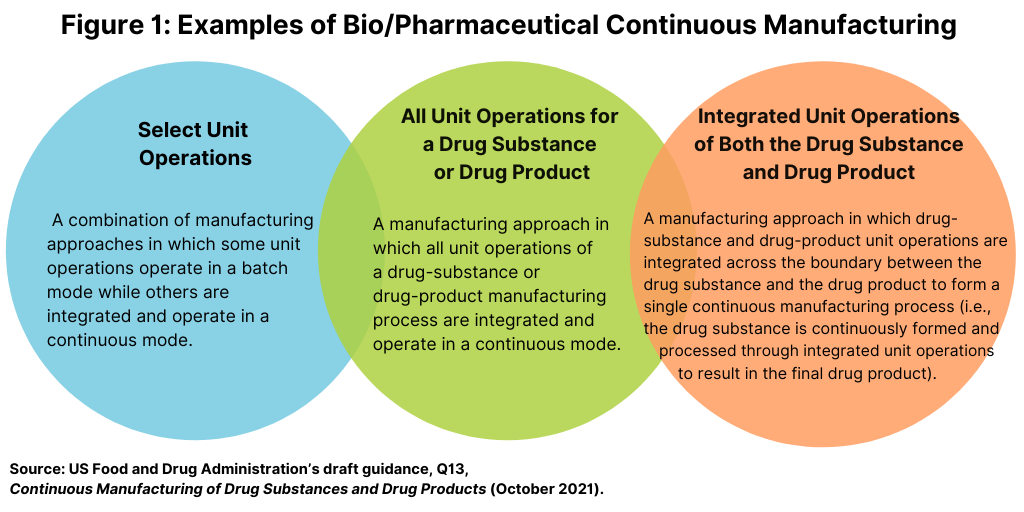

Continuous manufacturing refers to the uninterrupted production process where materials are constantly fed into the system, and products are continuously manufactured, as opposed to the traditional batch production method. This approach allows for a streamlined flow of production, reducing downtime between processes and eliminating many of the inefficiencies associated with batch processing.

Key Benefits of Continuous Manufacturing

At Alfa Remedies, continuous manufacturing has revolutionized the way we produce pharmaceutical products. Here are the key benefits we’ve experienced:

1. Increased Efficiency

With continuous manufacturing, Alfa Remedies is able to produce pharmaceuticals at a faster rate compared to traditional batch processing. The process eliminates the need for frequent start-up and shutdown times, which are often required in batch production. As a result, we can manufacture large quantities of medicines with minimal interruptions, ensuring timely Pan India delivery.

2. Enhanced Quality Control

Continuous manufacturing allows for real-time monitoring and quality control at every stage of the production process. This ensures that any deviations from quality standards can be immediately identified and corrected, leading to fewer defects and higher consistency in product quality. At Alfa Remedies, maintaining stringent quality standards is our top priority, and continuous manufacturing helps us achieve that.

3. Reduced Waste and Cost Savings

The continuous nature of this production method leads to a significant reduction in waste. By optimizing the use of raw materials and reducing the time spent on non-productive activities like equipment cleaning and maintenance, continuous manufacturing contributes to lower operational costs. For a pharma manufacturer like Alfa Remedies, this translates to cost-effective production while ensuring that high-quality medicines reach patients across India.

4. Improved Scalability

One of the standout advantages of continuous manufacturing is its scalability. Whether the demand is for a small-scale or large-scale production, Alfa Remedies can easily adjust the output to meet market demands without major changes to the manufacturing process. This flexibility is particularly beneficial in today’s dynamic healthcare environment, where demand for pharmaceutical products can change rapidly.

5. Faster Time-to-Market

With continuous manufacturing, Alfa Remedies can reduce the time it takes to bring new pharmaceutical products to market. The streamlined process, combined with real-time quality monitoring, enables us to produce and deliver medicines more efficiently. This is crucial in an industry where timely access to medicines can save lives and improve patient outcomes.

Continuous Manufacturing and Quality Assurance

At Alfa Remedies, quality assurance is a cornerstone of our pharmaceutical production process. Continuous manufacturing enhances our ability to ensure that every product meets the highest standards of quality and safety. Here’s how:

- Real-Time Data Monitoring: Continuous manufacturing systems are equipped with advanced sensors and IoT devices that provide real-time data on production variables like temperature, pressure, and material flow. This allows our teams to monitor the process continuously and make adjustments as needed to maintain consistent quality.

- Automated Quality Control: Automated systems in continuous manufacturing enable rapid testing and validation at every stage of production. This minimizes the risk of human error and ensures that only products that meet stringent quality criteria are released into the market.

- Compliance with Regulatory Standards: Continuous manufacturing aligns with regulatory standards set by agencies like the FDA and EMA. With real-time monitoring and data documentation, Alfa Remedies can easily demonstrate compliance with industry regulations, ensuring patient safety and product reliability.

The Future of Continuous Manufacturing in Pharma

As the pharmaceutical industry continues to evolve, continuous manufacturing is expected to play an even more prominent role. Alfa Remedies is committed to staying at the forefront of this innovation by integrating Industry 4.0 technologies such as AI, IoT, and predictive analytics into our continuous manufacturing processes. These technologies will further enhance our ability to produce high-quality medicines efficiently and deliver them reliably across India.

Conclusion

![]()

Continuous manufacturing has proven to be a transformative approach in the pharmaceutical industry, offering numerous benefits such as increased efficiency, enhanced quality control, reduced waste, and faster time-to-market. At Alfa Remedies, we are proud to embrace this cutting-edge production method, ensuring that we deliver high-quality medicines to patients across India with speed and reliability.

As a leader in pharmaceutical manufacturing, Alfa Remedies is dedicated to leveraging the latest technologies and production methods to meet the growing needs of the healthcare sector. Contact us today to learn more about our continuous manufacturing capabilities and how we can support your business needs.