Introduction

The pharmaceutical industry is known for its stringent measures, where manufacturing projects often set benchmarks for innovation, efficiency, and quality. Below are several case studies that provide insights into the triumphs and lessons learned from various pharma manufacturing projects.

1. Change with Smart Manufacturing

What the company did: Following an acquisition, the company streamlined its manufacturing process through smart factory transformation in collaboration with Cognizant. This transformation utilized a unified Manufacturing Execution System (MES) across 70 locations worldwide, resulting in a 20% increase in throughput and a 50% reduction in batch review efforts.

Cost Savings: The company reduced inventory costs by 10% and rework by 15%, saving over 4,000 person-hours.

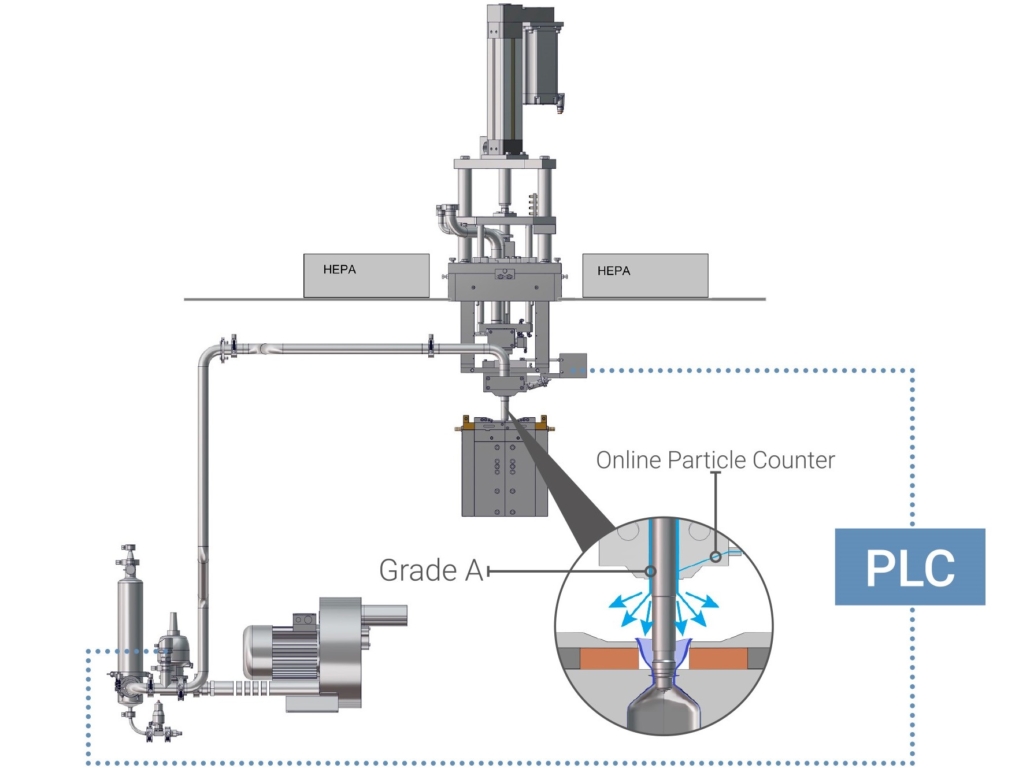

2. BFS Operations

Project: Catalent Pharma Solutions successfully managed the technical transfer of an ophthalmic product to its Blow-Fill-Seal (BFS) manufacturing facility in Woodstock, Illinois.

- Facility Upgrade: The formulation and filling suite was upgraded with a new air-handling system.

- Automated Systems: An automated formulation skid was designed and qualified, and the BFS filling machine was upgraded.

- Regulatory Approval: The facility complied with the U.S. FDA’s manufacturing and marketing requirements.

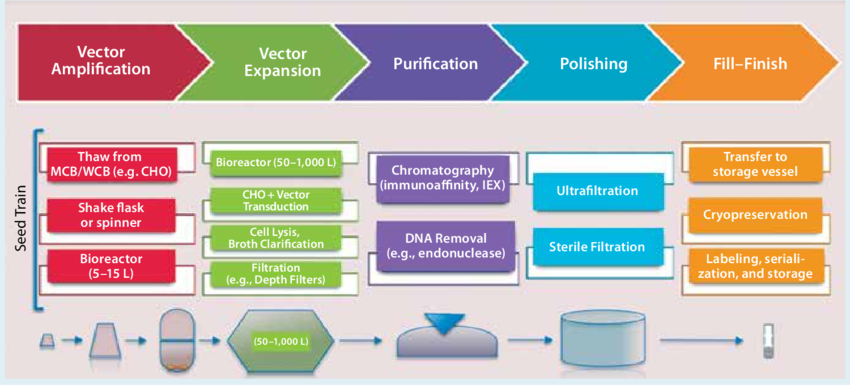

3. Manufacturing of Viral Products

Project: SAFC, a MiliporeSigma business unit, undertook a demanding viral product manufacturing project.

- Project Management: Careful planning and coordination were key to meeting project timelines and specifications.

- Technical Capabilities: Advanced technologies and methodologies were employed to ensure product quality and safety.

- Client Collaboration: The team worked closely with the client to identify obstacles and improve processes.

4. Real-Time Project Management in API Manufacturing

Project: Neuland Laboratories implemented real-time project management to enhance Active Pharmaceutical Ingredient (API) manufacturing.

Integrated Systems: The company used real-time data to manage and control production, leading to reduced cycle times, yield improvements, and continuous process optimization.

Conclusion

These case studies highlight the challenges and exceptional measures undertaken in pharmaceutical manufacturing. By leveraging smart technologies, effective project management, and rigorous quality control, these companies have set new benchmarks in the industry.